Sigma Suite V23 redefines nesting methods and course of optimisation

[ad_1]

Related store fabrication

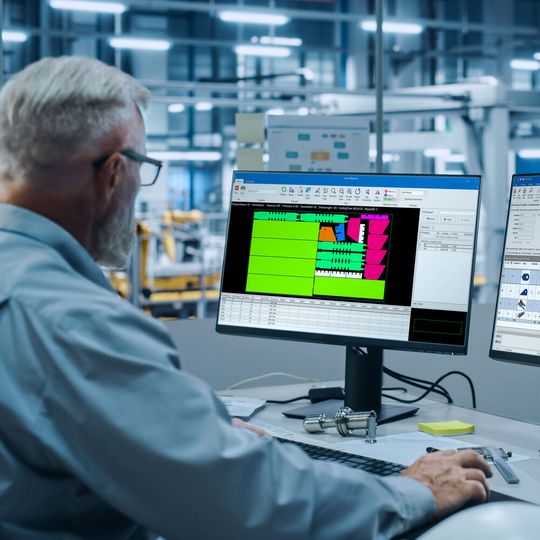

Sigma Suite V23 redefines nesting methods and course of optimisation

Supply: Cambrio

Associated Distributors

CAD/CAM firm Sigma Nest introduced model 23 of their software program suite. The flagship package deal delivers new nesting methods for real-world manufacturing that optimise half processing and workflow effectivity past traditional nesting for materials.

(Supply: Cambrio)

The most recent model of Sigma Nest’s Sigma Suite contains a number of new options. Aside from new nesting methods, it presents optimised workflows and expanded management. Additionally, three new Related Store apps complement store flooring administration. The Related Store is a set of software program instruments that connects the folks and processes in a store with the purpose to leverage the character of an operation. These digital connections mix all areas of a store into one holistic entity, reworking the flexibility to handle it successfully and effectively.

Making life simpler downstream has been a key focus of model 23 with a number of methods for pushing the workflow for assemblies or secondary operations and uncluttering the store flooring. For instance, Greatest Sheet with Blended Grouping retains elements of comparable materials collectively for many who program a number of days of labor without delay, or those that load sheets manually. Moreover, an enhanced array perform permits customers to dynamically drag the arrays of elements for the required amount of kits, assemblies, or mounted half configuration.

A number of nesting options at the moment are in-built for HD Trueshape and HD Superior Trueshape customers, who will achieve full entry to stack nesting, multi-torch nesting for giant elements, dynamic X & Y clearance, in addition to enhancements to Widespread Line nesting. Bump nesting updates embrace the flexibility to retain a boundary and keep away from nesting inside destructed notch areas, device dependent bump boundaries, half rotation primarily based on tooling, and customary reduce line bumping.

The model new Chill out Nest function can unfold elements out on the cropped space of a accomplished nest to create a stronger skeleton, lowering the danger of half tipping and half distortion from extra warmth.

A number of person expertise enhancements permit customers to optimise the method workflow as they profile reduce fairly than forcing them to begin over so as to add the choices for the nest, equivalent to removing of pre-piercing operations, crop reduce aspect choice, apply scrap reduce preferences, or apply confirmed firm customary defaults. Additional enhancements embrace assist for added fly reduce patterns and taper correction for 3D bevel and waterjet machines that alter the lean of the machine head throughout straight and bevel cuts.

Model 23 has some instruments to spice up the productiveness of the skilled punch programmer. Interactive nesting for Punch automates bump boundaries for every device, bettering the pace and precision of half placement. Punch patterns now permit for a number of contours. Single-click loading to the turret of instruments (together with complete sample device teams) utilizing the brand new Fast Drop function. Wheel-type instruments can profit from new skill to regulate the indexing angle of the device unbiased of the path of journey. Model 23 customers may even profit from extra detailed device reporting which incorporates device used inside every sample, sample membership for various instruments, and actionable alerts for incomplete tooling and floating scrap.

(ID:48734341)

[ad_2]

Source_link