A scientific survey of RUM course of parameter optimization and their affect on half traits of nickel 718

[ad_1]

Desk 4 depicts the outcomes of the present examine. It represents the typical values of MR and Ra of two experiments for every enter worth. It’s noticed that most MR is obtained in experiment run 1 whereas minimal roughness is obtained in experiment run 12. Three standards are used akin to lack-of-fit take a look at, the sequential mannequin sum of squares, and mannequin overview statistics. For higher outcomes, a backward elimination course of is used to get rid of the insignificant phrases within the fashions. This elimination course of enhances the adequacy of the mannequin by eradicating the non-significant phrases from the quadratic mannequin to protect the mannequin hierarchy.

Evaluation of MR and Ra

Tables 5 and 6 reveals the values of the outcomes after the backward elimination course of. It’s clear from Tables 5 and 6 that every one the enter parameters are vital. In addition to this, F values and P values additionally inform concerning the adequacy of the mannequin. This mannequin’s F Desk -value is evaluated by splitting the typical sq. worth of the mannequin into the typical sq. residual values. The F-value defines the relation between mannequin variance and the residual variance. If variance values are nearly equivalent, the fraction is sort of equal to 1 and the mannequin doesn’t have an vital affect on efficiency. The obtained F worth of the mannequin for MR and Ra is 472.61 and 47.598, respectively and for each MR and Ra the P-value are lower than 0.05. Tables 5 and 6 reveals that the mannequin obtained for MR and Ra important24.

The R2 known as the willpower coefficient which tells the diploma of closeness between experimental worth and predicted worth. The share of closeness to the 1 confirmed the great experimental worth towards the expected worth. Within the current work, the obtained R2 worth for MR and Ra got here out to be 98.7% and 96.9% respectively as proven in Tables 5 and 6. Some extra properties akin to adjusted R2, predicted R2 sufficient precision additionally performs an excellent function for the adequacy of the mannequin. It reveals wholesome settlement between experimental worth and predicted worth. “Enough precision” signifying the signal-to-noise ratio (S/N). Normally, the worth better than 4 is suitable25. In each ANOVA Tables 5 and 6 not solely particular person parameters but additionally in an interactive approach it influences response parameters i.e., MR and Ra.

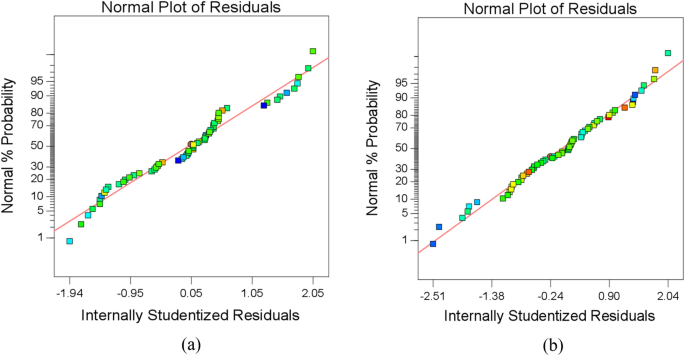

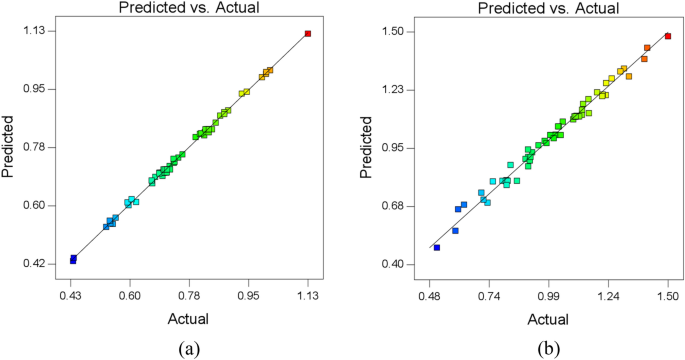

Determine 7 represents the usual residual chance curve which reveals that residues are inside ± 3 limits and that they’re mounted by the MR and Ra straight traces. Determine 8 demonstrates that the estimated mannequin values are true to MR and Ra experimental values. This reveals that ANOVA desk findings are dependable. Equation (2) and (3) represents the regression mannequin for MR and Ra respectively.

$$start{aligned} R = & + 3.52990 – 0.000542 instances Instrument, Rotation – 179.577 instances Feed ,Fee – 0.00812 instances Ultrasonic, Energy & – 0.00488 instances Diamond, Abrasive ,Grit ,Dimension & + 0.0362 instances Instrument ,Rotation instances Feed ,Fee + 0.523 instances Feed, Fee instances Ultrasonic, Energy & + 632.769 instances Feed,Fee^{2} + 0.0000217 instances Diamond ,Abrasive, Grit Dimension^{2} finish{aligned}$$

(2)

$$start{aligned} R_{a} & = 7.135 – 0.00122 instances Instrument ,Rotation + 71.014 instances Feed, Fee – 0.06371 & ;;;; instances Ultrasonic, Energy – 0.02914 instances Diamond ,Abrasive, Grit ,Dimension & ;;;; + 0.00001735 instances Instrument ,Rotation instances Ultrasonic, Energy – 1.608 & ;;;; instances Feed, Fee instances Ultrasonic ,Energy + 0.717 instances Feed, Fee instances Diamond, Abrasive, Grit ,Dimension & ;;;; + 0.0000715 instances Diamond, Abrasive, Grit, Dimension^{2} . finish{aligned}$$

(3)

Course of parameter impact evaluation

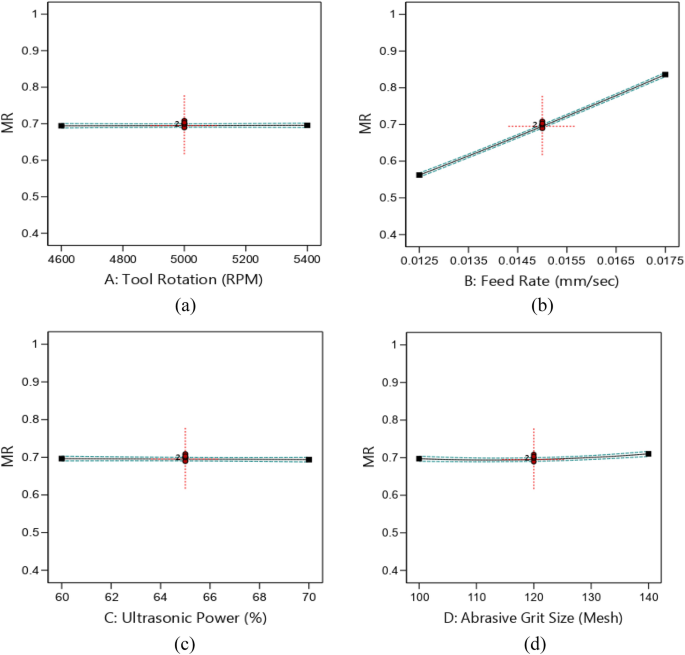

Determine 9 depicts the affect of parameters i.e., rotational pace (rpm), feed charge (mm/sec), ultrasonic energy score (%) and abrasive grit dimension (mesh) on machining charge. It’s noticed that rotational pace doesn’t considerably have an effect on the MR as proven in Fig. 9a. Conversely, it’s noticed that the MR is considerably modified from 0.5512 to 0.8525 mm3/sec with change within the penetration charge from 0.0125 to 0.0175 mm/sec as depicted in Fig. 9b. It’s attributed in direction of the deep grooving of abrasive particles at larger feed charge and resulted in larger MR. Determine 9c reveals the affect of ultrasonic energy on MR. It’s seen that the MR is elevated from 0.6965 to 0.7109 mm3/sec for a rise in energy from 60 to 65%. Additional improve in energy upto 70%, MR decreases from 0.7109 to 0.6937 mm3/sec. The obtained outcomes are according to the earlier examine of researchers26,27.

The impact of the dimensions of the diamond on MR is proven in Fig. 9d. Abrasive grit dimension is inversely proportional to the mesh worth of abrasive grit. It’s noticed that MR not considerably modified with change within the abrasive grit dimension. As well as, the curvature is noticed in abrasive grit dimension impact on MR. It is a sign of the dimensions of the grain of the diamond use in bonded instrument improve the machining charge. That is owing to deeper indentation of abrasive particles into the workpiece28.

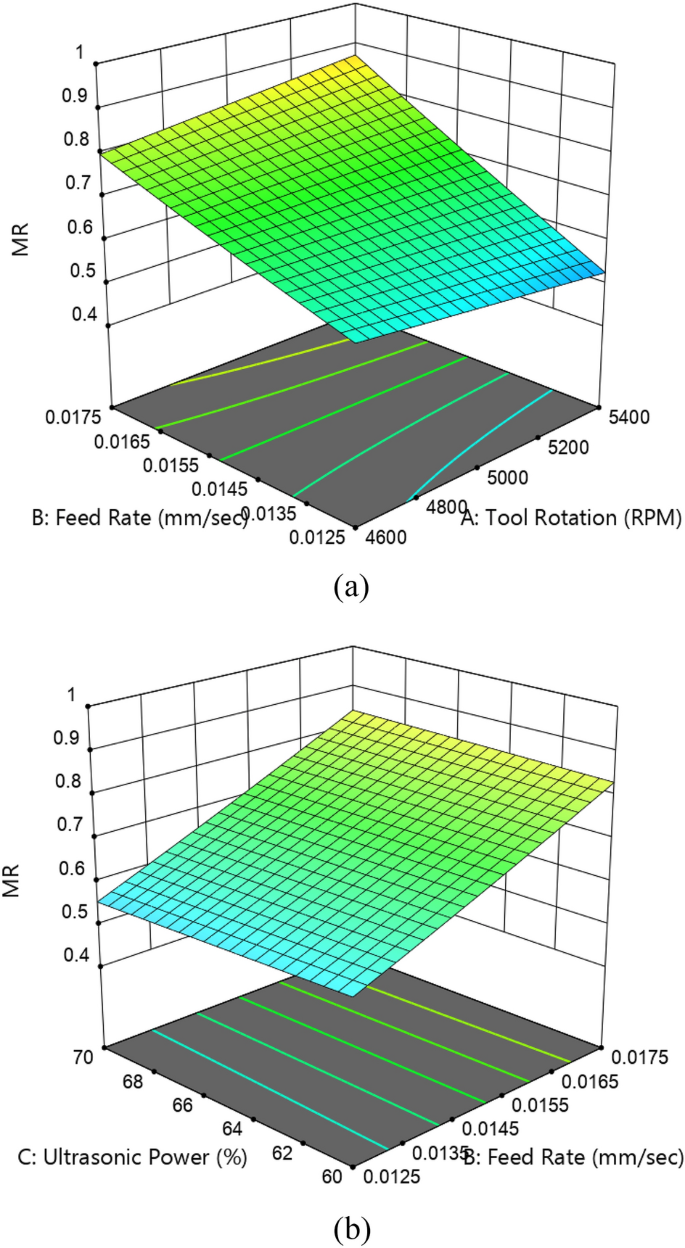

Determine 10a depicts the interplay results on MR. It’s verified from Eq. (2) that two interactions are discovered important for MR. It’s clearly seen that the utmost MR is obtained in a area the place feed charge and power rotation is excessive. It’s attributed in direction of the rise within the contact size of diamond abrasive particles. Conversely, minimal MR is noticed in a area the place feed charge is low and power rotational pace is larger. That is owing to decrease level of contact between the instrument and the workpiece. Interplay impact between the ultrasonic energy and feed charge on MR is proven in Fig. 10b. It’s noticed that MR is achieved to be most in areas the place feed charge and ultrasonic energy is most. This occurs attributable to improve within the vibration with improve within the ultrasonic pressure that eliminates swarf and particles effectively from machining surfaces. Alternatively, minimal MR is obtained at decrease penetration charge and ultrasonic energy.

Determine 11 illustrates the affect of course of parameters on the machined floor. Determine 11a depicts the impact of instrument rotational pace on Ra. It’s concluded that the Ra is decreased with improve within the instrument rotational pace. It’s attributed in direction of the enhancement within the grinding motion per unit time of the instrument with improve within the rotational pace. Another excuse for higher floor roughness is to cut back the event charge of micro-cracks on the floor29. Determine 11b reveals the impact of feed charge on Ra. It’s noticed that the Ra is elevated steeply from 0.676 to 0.938 µm with a rise in penetration charge from 0.0125 to 0.0175 mm/sec. This improve is owing to the extension within the micro-cracks on the workpiece floor. The impact of ultrasonic energy on Ra is proven in Fig. 11c. It’s discovered that the Ra is decreased with improve within the ultrasonic energy. This alteration shouldn’t be discovered to be important. Furthermore, additionally it is noticed that the amplitude distinction has no impact on the Ra. Determine 11d depicts that Ra is decreased from 0.861 to 0.807 µm with improve in grit dimension from 100 to 120 mesh dimension. Conversely, it’s elevated little from 0.807 to 0.811 µm as grit dimension will increase from 120 to 140 mesh. That is owing to coarse abrasive grains that ends in enhancement of fracturing charge. As well as, in the course of the RUM course of, the diamond particles repeatedly transfer within the gap cavity. The elevated dimension of the granulate will increase the frictional forces on the lateral interface and contributes to the floor harm incurred by this uniform lateral put on30.

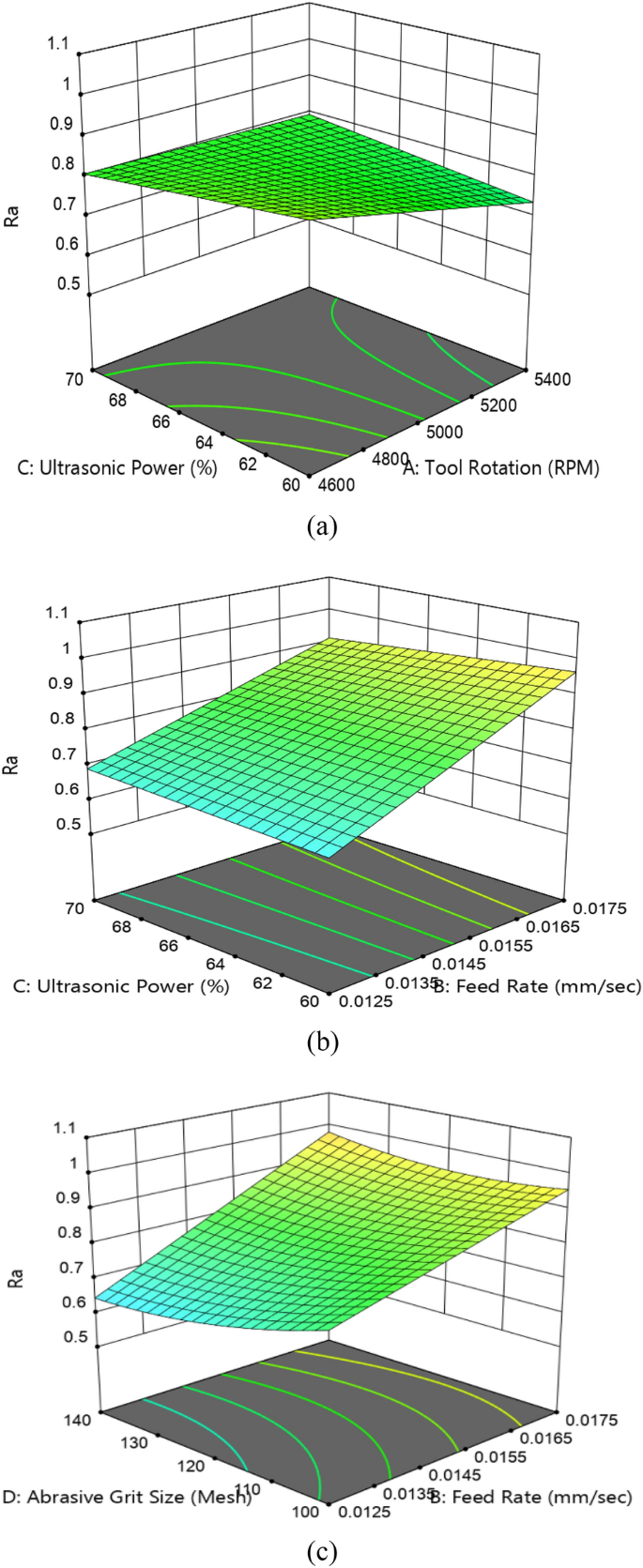

Figures 12 illustrates the interplay impact on Ra. It’s verified from Eq. (3) that three interactions are discovered to be important for Ra. Determine 12a reveals the combo impact of ultrasonic energy and power rotational pace. The minimal worth of Ra is obtained in an space the place ultrasonic energy is minimal and power rotational pace is most. That is owing to a rise within the grinding cross of the instrument that ends in the fineness of machining surfaces. The interplay impact of feed charge and ultrasonic energy on Ra is depicted in Fig. 12b. The minimal Ra of 0.665 µm is obtained in a area of low feed charge and low ultrasonic energy. It’s owing to decrease abrasive diamond indentation depth on the workpiece. The utmost Ra of 0.965 is present in a area the place feed charge is most and ultrasonic energy is minimal. That is owing to larger indentation depth of abrasive particles on the workpiece floor. Determine 12c reveals the impact of feed charge and abrasive grit dimension on Ra. It’s clearly seen in Fig. 12c that the minimal worth of Ra i.e., 0.762 µm is obtained for low feed charge and high-quality grit dimension (140 mesh). It’s attributed in direction of decrease indentation depth of diamond particles on the workpiece floor. The worth of Ra is most at larger feed charge in any respect abrasive grit dimension. That is owing to a change within the grit dimension from coarse to high-quality i.e., 0.9083 µm31.

Microstructural evaluation of machined floor

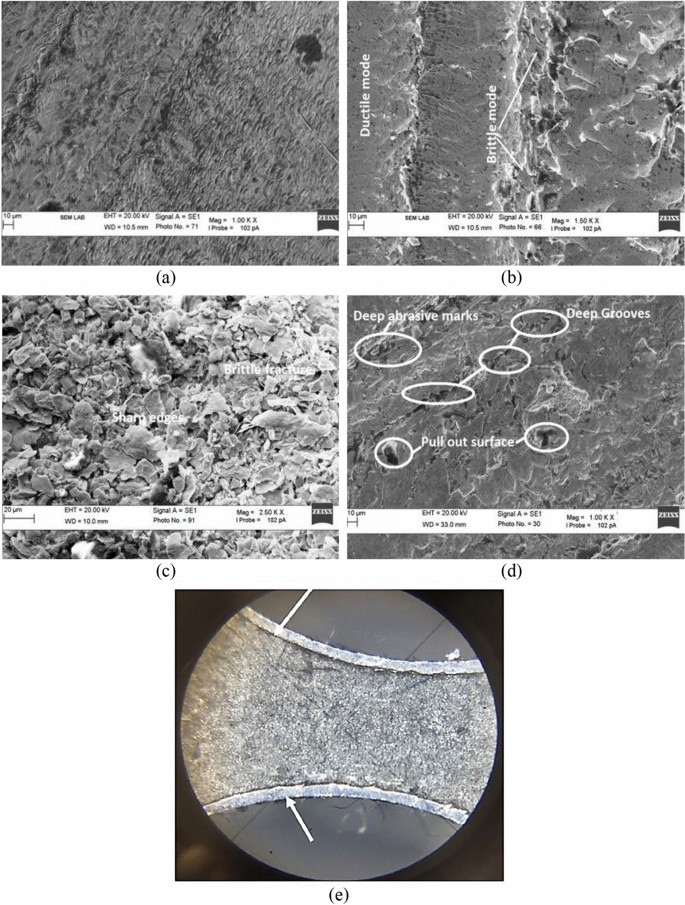

The SEM machine is utilized to review the floor of base materials, most floor roughness specimen (experimental run 3, minimal floor roughness specimen (experimental run 12) as proven in Fig. 13. That is evident from Fig. 13a that the floor of the bottom materials (Inconel 718) is uniform with none micro-cracks and grooves. Conversely, the machined surfaces consisted of microcracks and grooves on the floor. Determine 13b and c depicts the surfaces of most roughness surfaces. Two sorts of fracture are noticed on the machined floor of most floor roughness i.e., ductile fracture and brittle fracture as proven in Fig. 13b. As well as, sharp edges, deep holes, and micro-cracks are additionally noticed on the machined floor as proven in Fig. 13c. Resulting from excessive feed charge of the instrument, the fabric faraway from the floor in greater chunk. Moreover, generally depleted edges are additionally noticed on the machine floor. It is a sign of brittle fracture that confirmed the promulgation of intergranular and trans-granular cracks. These kind of surfaces are noticed owing to vibration motion of the instrument in the course of the course of. Determine 13d depicts the machined floor of minimal floor roughness. Small holes and deep abrasive marks are noticed on the floor. Furthermore, the sting high quality of the machined workpiece can also be analysed by utilizing an optical microscope as proven in Fig. 13e. There isn’t a crack and burr is noticed on the drilled gap edge.

Optimization by means of particle swarm optimization

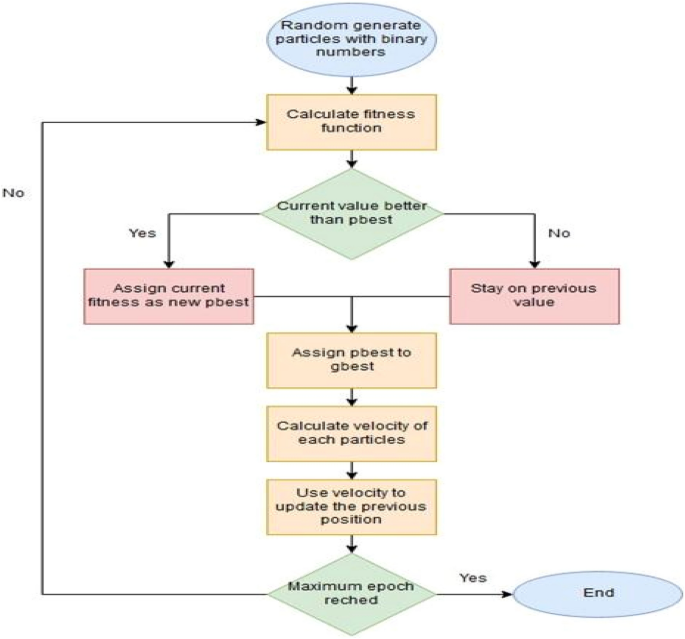

The phrase “Optimization” means to make the absolute best use of sources. In current analysis, a metaheuristic optimization approach i.e., particle swarm optimization (PSO) can also be used to get the optimum values of course of parameters of RUM for Inconel 718. In response to greatest data of the creator, Kennedy and Eberthart32 launched PSO in 2006. It’s a stochastic algorithm that’s able to fixing optimization issues with the evolutionary algorithm akin to genetic algorithm, differential evolutionary, and so on. This system can also be able to producing the meals looking out behaviour of society akin to a chook swarm or college of fish. Every member of the swarm in PSO is taken into account a particle. Every particle within the search area represents the potential resolution. As well as, the knowledge collected from the particles is sorted for getting the very best particle within the swarm akin to world greatest (gbest).

Furthermore, every particle place is outlined when it comes to vectors akin to place vector and velocity vector. The place and the speed vector of the (i^{th}) particle within the d-dimensional search area will be expressed as (x_{i} = left( {x_{i1} , x_{i2} , …, x_{id} } proper)) and (v_{i} = left( {v_{i1} , v_{i2} , …, v_{id} } proper)) respectively. The perfect location of every particle relies on the consumer outlined health perform i.e. (p_{i} = left( {p_{i1} , p_{i2} , …, p_{id} } proper)), denoted as pbest and the fittest particle discovered within the full set of swarm is (p_{g} = left( {p_{g1} , p_{g2} , …, p_{gd} } proper)), denoted as gbest. The each values are akin to its greatest health values at time (t). Equation 4 and 5 are used for calculating the brand new positions and new velocity vectors for subsequent health analysis at time (t + 1).

$$x_{id} left( {t + 1} proper) = x_{id} left( t proper) + v_{id} left( t proper)$$

(4)

$$v_{id} left( {t + 1} proper) = w_{id} left( t proper) + c_{1} rand_{1} left( {p_{id} left( t proper) – xidleft( t proper)} proper) + c_{2} rand_{2} left( {p_{gd} left( t proper) – x_{id} left( t proper)} proper)$$

(5)

the place (rand_{1}) and (rand_{2}) are the random values which fall between (0, 1), w is the issue inertia weight, and used to present the course of earlier velocities on the current particle velocity, (c_{1}) is cognitive studying issue that reveals the motion of particle towards its personal success and (c_{2}) defines the social studying issue which reveals {that a} particle strikes towards close to its neighbour’s worth. Some researcher has advised the ranges of (c_{1}) as (1.5 to 4) and (c_{2}) as (2 to 2.5). Determine 14 represents the movement chart of PSO approach.

Coding of particles

The binary code is used to generate the particle in PSO. The binary format particle is decoded by utilizing Eq. 6. The accuracy is given by Eq. 7.

$$X_{i} = X_{i}^{l} + frac{{X_{i}^{U} – X_{i}^{L} }}{{2^{n} – 1}}S_{i}$$

(6)

the place (X_{i}): the decoded worth of RUM parameters. (X^{L}): is the decrease restrict of RUM parameters. (X^{U}): the higher restrict of RUM parameters. n: is the substring size (= 4). (S_{i}) is the decoded worth of the (i^{th }) particle

$$Accuracy = frac{{X^{U} – X^{L} }}{{X^{n} – 1}}.$$

(7)

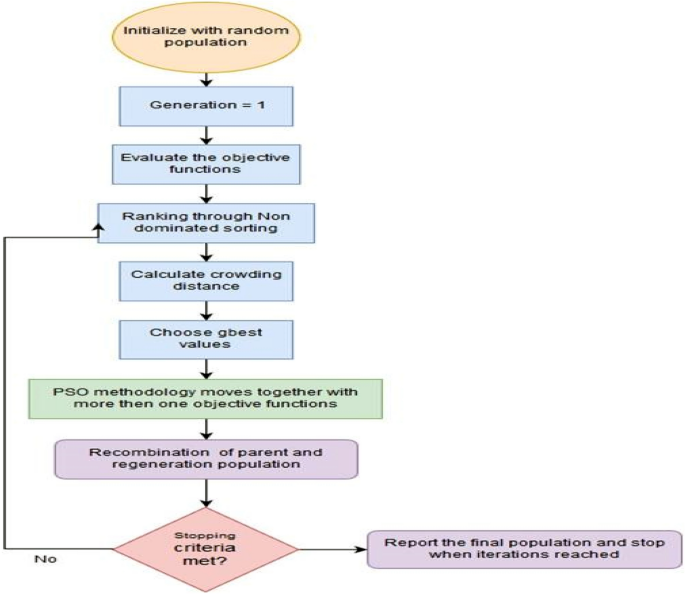

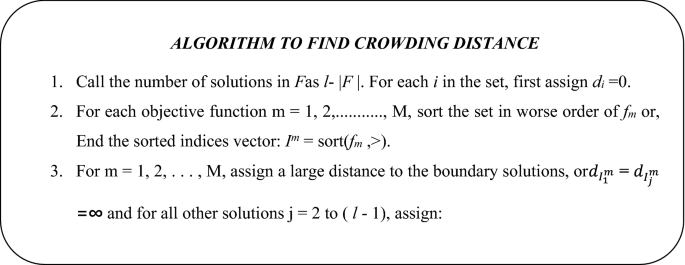

Crowding distance

The crowding distance is a key idea for sorting the choices into upward goal values. It’s the imply of two adjoining resolution values. Infinite crowding distance values are given to the boundary options which have the bottom and highest goal perform values, so they’re typically chosen. For every goal perform, this step is accomplished. An answer’s closing crowding distance worth is set by making use of all of the completely different crowding distance values to every goal perform. The algorithm for crowding distance is listed under.

Determine 15 represents the multi-objective PSO (MOPSO) movement chart. The algorithm for MPSO is listed under.

The place (rand_{1}) and (rand_{2}) are random numbers between 0 and 1. If the present place past the bounds takes the higher or decrease limits and its velocity is generated randomly. Lastly carry out the steps 2–5 till stopping standards are met.

Within the present analysis work, MR and Ra each responses are opposing in design. It means larger worth of machining charges resulted in larger worth of floor roughness. As a way to obtain a better machining charge with higher floor ending, optimum parameter’s values should be obtained. For locating the higher worth of the machining charge and floor roughness, single and multi-objective PSO is used. The decrease and higher certain values of the parameters are utilized in algorithm in order that the worth shouldn’t go over certain. The values are given in Desk 7.

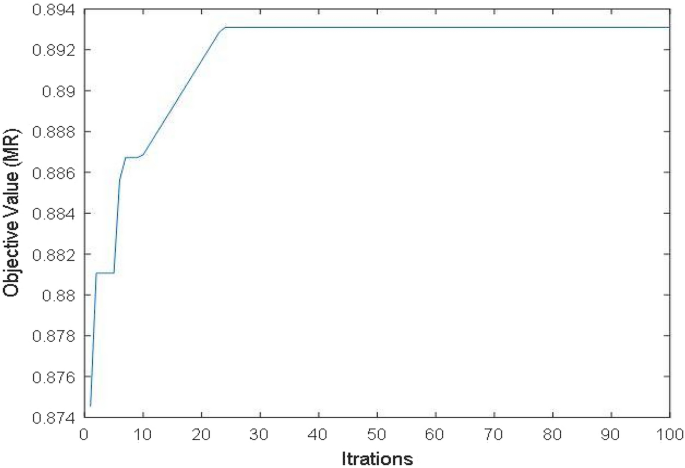

Maximization of MR

The developed empirical mannequin [Eq. (2)] is utilized for implementing the PSO approach. Determine 16 depicts the values of MR with every iteration after using the PSO approach on empirical fashions. After successive iterations, PSO provides the utmost worth of MR (0.8931 mm3/sec) at parameters mixture of Instrument Rotation-5400 rpm; Feed Fee-0.0175 mm/sec; Ultrasonic Energy-70%; Diamond Abrasive Grit Dimension- 140 mesh depicted in Desk 8.

Minimization of R

a

To foretell decrease worth of Ra, the empirical mannequin (Eq. 3) is utilized in PSO. The expected values of Ra for every iteration throughout PSO approach is depicted in Fig. 17. After successive iterations, PSO provides the minimal worth of Ra (0.554 µm) at parameters mixture of Instrument Rotation- 5400 rpm; Feed Fee-0.0125 mm/sec; Ultrasonic Energy-60%; Diamond Abrasive Grit Dimension- 140 mesh depicted in Desk 9.

For the validating these outcomes affirmation checks are carried out on RUM with two replication and the expected values and common values of confirmatory experimental outcomes (for MR and Ra) are additionally tabulated in Desk 9. The confirmatory outcomes for MR and Ra have been discovered to vary from predicted values by 3.42% and three.14% respectively that are discovered inside the 95% confidence interval (CI).

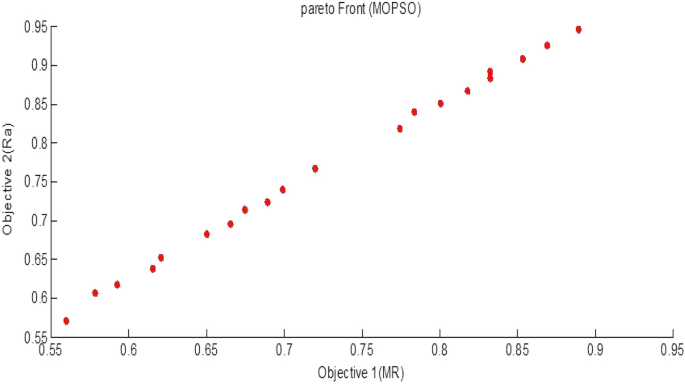

Multi-response optimization utilizing MOPSO

Multi goal evolutionary algorithm produces a Pareto entrance for the multi-objective minimization drawback, which may discover out a trade-off resolution between conflicting targets. The Pareto entrance is outlined because the set of non-dominated options, the place every goal is taken into account as equally good. An issue will be expressed when it comes to a Pareto entrance multi-objective optimisation drawback. From this standpoint, given two options s and s′, s′ dominates s if and provided that relevance (s′) > relevance(s) and |s′| <|s|. Nonetheless, if relevance (s′) > relevance(s) however |s′| >|s|, neither resolution can dominate the opposite. The gathering of all non- dominating options constitutes a floor known as Pareto entrance. The Pareto entrance consists of these resolution for which there exists no higher resolution in each standards . Utilizing Pareto entrance optimisation for a range drawback, there is no such thing as a want for any a priori assumptions concerning the significance of targets33 .

The crowding distance based mostly MOPSO algorithm (In “Optimization by means of particle swarm optimization” part) can also be employed for acquiring the optimized values of course of parameters for MR and Ra. The empirical fashions based mostly on Eq. (2) and (3) each are used for getting the optimized values of course of parameters utilizing MOPSO. The pareto entrance for goal capabilities MR and Ra is proven in Fig. 18. The Pareto entrance is the set of all Pareto environment friendly options. In muti goal optimization, numerous options are generated as tabulated in Desk 10. The options are used for getting the very best values of course of parameters for acquiring most values of MR and minimal values of Ra at optimized course of parameters. For the affirmation of the outcomes obtained by MOPSO and discovering the effectiveness of the optimization approach (MOPSO) some affirmation checks (Sr no. 1 and a pair of) are carried out on the workpiece and the Desk 11. reveals that the confirmatory outcomes for MR and Ra have been discovered to vary from predicted values by 3.46% and 4.5% respectively that are discovered inside the 95% confidence interval (CI).

[ad_2]

Source_link