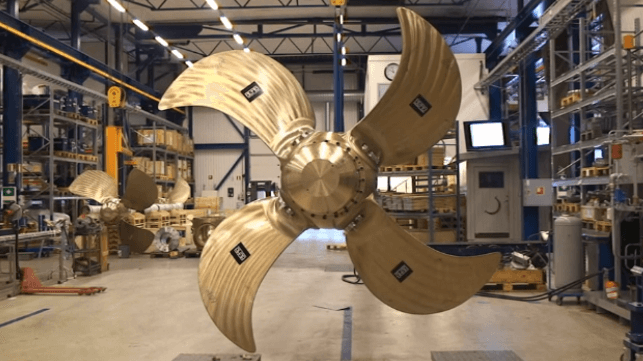

Propeller Optimization Positive factors Significance as Focus Turns to Effectivity

[ad_1]

The inexperienced transition in transport is centered squarely on different fuels, however effectivity is important as nicely. An environment friendly ship wants much less power to function, and because the IMO’s new emissions guidelines take impact, increased effectivity interprets into decrease value of compliance. This has created a much bigger position for suppliers like Berg Propulsion, the Swedish propeller builder identified for maximizing effectivity. To study extra, TME caught up with Mattias Dombrowe, Enterprise Supervisor – Electrical System Integration, Berg Propulsion to listen to about how propeller configuration can decrease gasoline value – and convey current ships into line with new laws.

TME: How is the decarbonization drive altering the propulsion market?

We see that decarbonization and effectivity are the way in which of the longer term, and the CII and EEXI are a giant driver for us. Shipowners want to fulfill these necessities. If we take a look at the enterprise mannequin for propulsion adjustments previously, we used to deal with the return on funding – however now it is extra about what it takes to be allowed to function beneath the brand new guidelines.

TME: What sort of effectivity positive factors are potential with adjustments to the propeller?

There’s a variety, relying on the vessel and the working profile. The most important positive factors are potential when you’ve a considerable variation between the vessel’s design velocity and the velocity at which it truly operates. If the ship has a propeller that isn’t optimized for its actual working velocity, and then you definately set up a brand new propeller blades optimized for that velocity, then you definately make a big acquire. In that case, there shall be a transparent distinction.

It actually varies for every challenge, however on common, we see effectivity enhancements within the vary of six to 12 p.c. We don’t wish to brag, however in one in all our perfect instances, the distinction was 20 p.c.

TME: What’s the course of for designing probably the most environment friendly propeller for a ship?

With propeller design, it’s kind of such as you’re designing for a race automotive or a monster truck. Some ships function loads of the time at excessive masses and excessive speeds, and a few ships go slower. The secret is to know the operation profile and design a propeller for the aim.

TME: Berg Propulsion additionally works fairly a bit with the offshore trade – are you able to inform us what you are seeing in that market?

On the offshore facet, we see that extra vessels are coming again into service. Homeowners are additionally beginning to discuss new vessels once more, as a result of since 2014 there have been only a few offshore vessels ordered. The typical age for a “younger” offshore vessel is now about eight years.

We see that the operators are reactivating their latest vessels and upgrading them to the next commonplace. For instance, we’re delivering additional tunnel thruster packages for offshore vessel improve tasks for increased DP notation, together with electrical motors and drives. Geographically, we see the Center East and Southeast Asia as particularly lively at the moment.

We have additionally not too long ago partnered with Singapore’s Evolution Ideas to design a zero-emission offshore assist vessel utilizing our propulsion options, and there shall be extra information on that challenge to observe.

TME: What does Berg’s scope of labor appear to be on a sophisticated newbuild challenge?

Prior to now, the design course of would begin with the principle engines, that are the biggest capital funding within the vessel. Diesel engine sizes are comparatively strict, and you’re boxed into totally different energy ranges: you both have the six cylinder engine, or you’ve eight cylinder engine.

With a battery-powered vessel, the associated fee per kilowatt hour of energy is costlier. If we’re concerned early within the design course of and might save 100 kilowatts on the propeller facet by higher effectivity, then we will save 100 kilowatts on the electrical motor, the drives, the gen units and the batteries. When you may make these adjustments on the stage of kilowatts, as you’ll be able to with a hybrid propulsion system, it can save you cash. That’s the idea that we’re sharing with our prospects – the worth of getting us concerned early within the discussions. From the outset, we actually attempt to perceive how they are going to use the vessel in order that we will tailor the complete system to their wants.

Since Berg additionally presents electrical integration, we perceive the complete package deal for hybrid vessels, from the propeller wash all the way in which to the ability technology. We construct full methods, together with the operator’s controls and automation. By making hybrid methods easy for the crew to function, we may help them benefit from every system’s most effectivity.

[ad_2]

Source_link