Life-cycle accounting and value optimization: How useful resource cleansheet evaluation can assist

[ad_1]

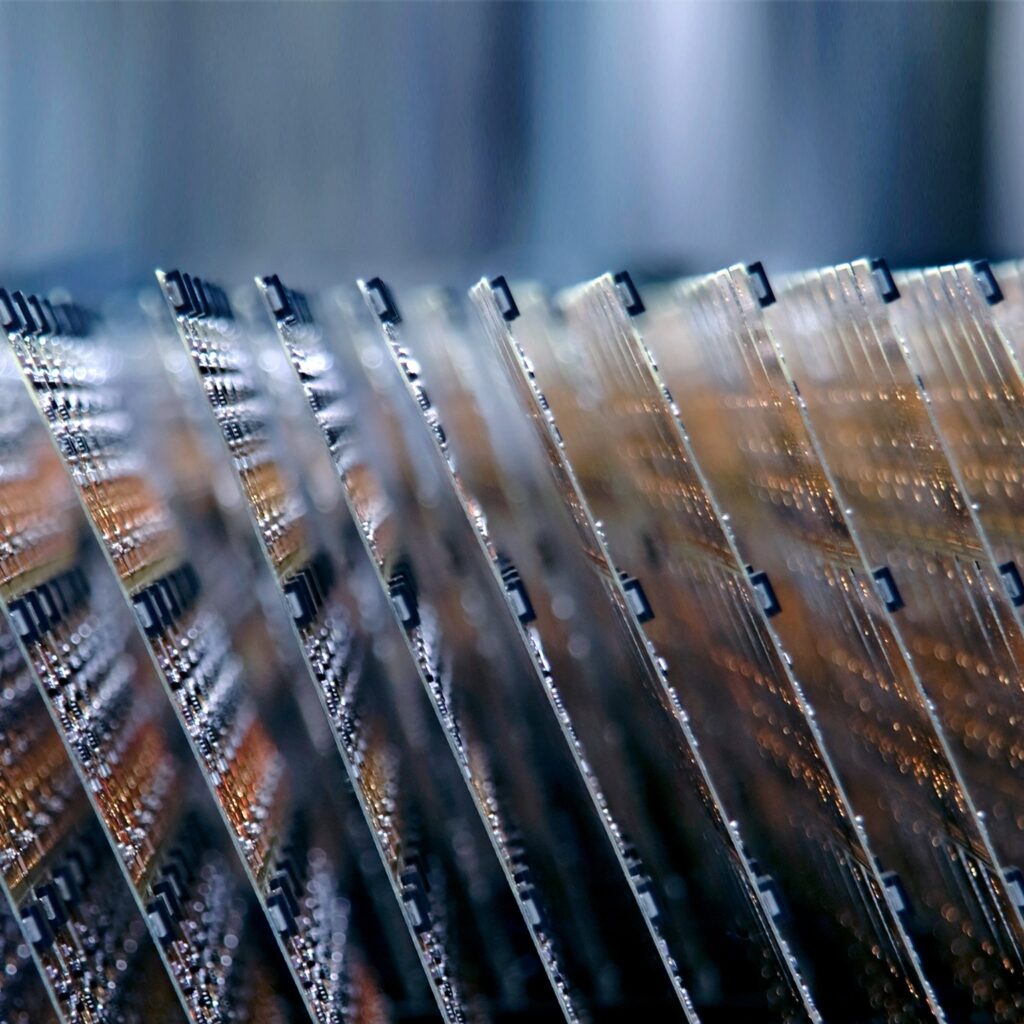

As world temperatures proceed to rise, manufacturing industries face a sustainability problem. The semiconductors that sit on the coronary heart of {most electrical} gadgets require copious quantities of power to fabricate and function. On the identical time, in a low-margin trade, prices are rising quick. Latest advances in analytics present a approach for firms to get a grip on these associated variables and gauge their impacts on the manufacturing course of. Useful resource cleansheet evaluation combines classical value cleansheet evaluation and environmental life-cycle evaluation to assist firms make important amenities selections and add worth to the underside line.

From supplies sourcing to manufacturing, transport, utilization, and end-of-life processes, most {hardware} is extremely power dependent. Within the manufacturing of pc chips, for instance, power consumption accounts for about 63 p.c of emissions.

And the worldwide info and communications know-how (ICT) trade is consuming extra electrical energy yearly. By 2030, it’s projected to account for 20 p.c of complete power demand, primarily related to networking and knowledge facilities.

To offset high-emissions depth, main firms are investigating methods to scale back their carbon footprints. And lots of are beginning at first of the design course of. This displays the truth that extra emissions alongside a product’s life cycle have been shifting from operations towards manufacturing in recent times. One purpose is that many trendy merchandise, from telephones to jet engines, are powered by electrical energy and are subsequently far more operationally environment friendly than their predecessors. Moreover, most of the newest merchandise embody options, equivalent to excessive computation energy and shows, which are carbon intensive to provide. Lastly, there may be an irresistible logic to baking in sustainability from the get-go. Our evaluation means that R&D accounts for five p.c or much less of the price of a product, but it surely influences as much as 80 p.c of its useful resource footprint.

To offset high-emissions depth, main firms are investigating methods to scale back their carbon footprints. And lots of are beginning at first of the design course of.

McKinsey’s Useful resource Cleansheet Resolution (RCS) maps a product’s or service’s value and CO2 footprint alongside its complete worth stream and life cycle. The answer is predicated on the established idea of value engineering—the methodology that firms use to carry transparency to the manufacturing prices, specs, and options of any mission or product, in addition to the full value of possession over time. Price engineering is about designing and implementing specs on the lowest complete value of possession, balancing design with the prices of procurement, manufacturing, meeting, and in-service assist. The advantage of RCS is that the identical, rigorous modeling utilized in value engineering is retooled to calculate CO2 emissions. It leverages bottom-up evaluation to gauge emissions components for each upstream and downstream actions in product manufacture and use. This permits firms to acquire an end-to-end view of emissions footprints, from the kind of machines used to cycle instances, packaging, and energy sources—and to match them aspect by aspect with the respective prices.

When utilized successfully, RCS fills a spot in measuring and managing product sustainability. Particularly, it addresses the fee dimension that life-cycle accounting doesn’t cowl and is thus extra helpful when making enterprise selections that require trade-offs. Furthermore, the extra modeling burden is mild, suggesting it could present a chic resolution to an more and more urgent problem.

Detailed state of affairs evaluation

Armed with RCS fashions, firms can undertake detailed state of affairs analyses in product design. They will feed the outcomes into plant and element selections to judge how varied system-level trade-offs play out. The evaluation will also be used to gauge the monetary and emissions prices of creating modifications within the manufacturing course of, together with the impacts of constructing or shopping for new tools or parts. Procurement groups can analyze the complete vary of choices and provider choices, doubtlessly offering incentive for different suppliers to modify to low-carbon manufacturing strategies.

By means of instance, one utility is within the manufacturing of aluminum merchandise. Right here, RCS can elicit emissions components from manufacturing processes and the transformation to a semifinished state. The identical logic could be utilized to product manufacturing and delivery.

Whereas RCS is a general-purpose methodology, it will also be utilized discretely to particular elements of the product life cycle. For cradle-to-gate evaluation, for instance, it will probably generate prices and emissions components which are immediately related to design, main assets, and early-stage processes.

The emissions knowledge generated by RCS evaluation is restricted to a person producer’s actions and can be utilized to mannequin a spread of situations to realize completely different value impacts. Aluminum produced in location X and refined in location Y would produce emissions Z, whereas different areas would produce a unique emissions footprint and incur a unique value issue.

By means of this method, firms can resolve on a steadiness of prices and emissions to go well with their strategic priorities.

Useful resource cleansheet evaluation in motion

To exhibit the facility of RCS, we utilized the methodology to parts of a single electronics product, calculating the cradle-to-gate life-cycle value and carbon footprint for 3 designs of an onboard charger for an electrical car.

Every of the designs used a unique energy semiconductor element: SiC-MOSFETs,

Si-IGBTs,

or Si-MOSFETs.

SiC-MOSFETs, made from silicon carbon, could be operated at a a lot larger temperature than the alternate options, assist larger switching frequencies, and supply larger present densities. In energy functions equivalent to onboard chargers, these benefits result in smaller models with decrease energy losses and, subsequently, larger ranges of effectivity. However, SiC-MOSFETs are two to 5 instances dearer than their silicon counterparts and IGBTs.

We assorted the SiC-MOSFET design with IGBTs and Si-Superjunction transistors, changing energy stage transistors and adjusting aluminum warmth sink sizes. In all three designs, we used unchanged, smaller SiC-design DC-link capacitors and inductors. This led to underestimated prices and emissions for IGBT and Si-MOSFET variants, for the reason that decrease switching frequency would require bigger parts than the SiC design.

To first calculate manufacturing life-cycle prices, we created a invoice of supplies, enhanced with extra geometrical info, after which calculated the prices of some custom-made inductors, transformers, and mechanical parts, equivalent to warmth sinks. For printed circuit boards (PCB), we used a proprietary value mannequin.

For the semiconductor carbon footprint calculation, we used the element die space as a fundamental parameter, measured by opening element packages. We multiplied that by an area-specific carbon emissions equal. For passive parts, we used literature values, verified with third-party knowledge. And for PCBs, we leveraged a parametric Excel mannequin with base literature values, making an allowance for PCB dimension and layer stack.

The evaluation revealed that the Si-MOSFET die was related to 0.58 kilograms (kg) carbon dioxide equal (CO2e), whereas the smaller IGBT die was related to 0.25 kg CO2e. The SiC MOSFET die produced 0.23 kg CO2e. By means of the fabric and meeting course of, we confirmed that the CO2 emissions for the three models have been 67.8 kg CO2e, 63.9 kg CO2e, and 61.8 kg CO2e, respectively (Exhibit 1). On a relative printed circuit board meeting (PCBA) value foundation for materials and meeting, by which SiC-MOSFET is ready at 100 p.c, the Si-IGBT unit got here out at 90 p.c, and the Si-MOSFET was 95.8 p.c.

Exhibit 1

Drilling down into particular person parts of the SiC-MOSFET design, the largest sources of emissions have been the capacitors, accounting for 22.8 kg CO2e, with the warmth sink coming in second at 11.5 kg CO2e (Exhibit 2). On a relative value foundation, the built-in circuits and the capacitors have been costliest.

Exhibit 2

Pulling all the varied strands of knowledge collectively exhibits that the design of the SiC variant produces a decrease value of wasted power, particularly throughout charging, which offsets larger supplies prices. The wasted energy at 6.6 kilowatt (kW) of load was 323.4 watts, in contrast with 422.4 and 455.4 for the Si-IGBT and Si-MOSFET designs, respectively.

Making an allowance for the charging value for various time spans and areas, in addition to wasted power, the SiC MOSFET design consistency outperforms in Europe, the USA, and China. Resulting from larger power prices, the best outperformance is in Europe and after 3,000 charging hours. Use-phase emissions after 1,000 hours of charging at 6.6 kW are greater than double cradle-to-gate emissions throughout all three designs (Exhibit 3).

Exhibit 3

RCS, which gives an built-in bottom-up method to modeling what merchandise ought to value, in addition to their carbon footprint, will permit stakeholders to judge trade-offs when making selections in the course of the improvement course of. As an example, RCS can assist reply questions equivalent to: “What are the life-cycle prices for carbon discount?” or “What’s the payback fee for larger efficiency choices, and what number of life cycle CO2 emissions can we save?” Amongst different use instances, RCS can carry readability at completely different determination factors in the course of the improvement and design of merchandise. It will also be helpful when groups are trying to pick the appropriate know-how for procured subcomponents, because it gives insights into their emissions and what they need to value.

The evaluation right here demonstrates how RCS can create a novel hen’s-eye view of sustainability impacts and prices. Successfully applied, the methodology will allow firms to take their inexperienced ambitions to the following degree, whereas making certain that they meet their regulatory obligations and the wants of the following era of sustainability-conscious shoppers. Most significantly, RCS insights are sensible and possible. Utilizing RCS as a part of the general McKinsey Catalyst Zero providing, firms can embark on large-scale transformations throughout their portfolios to generate actionable insights at scale.

RCS can be utilized throughout all phases of transformations, from baselining value and emissions footprints to evaluating financial carbon reductions and figuring out particular decarbonization targets. These insights can drive directed motion, enabling determination makers to create enterprise fashions that each add worth and set their firms other than their friends.

[ad_2]

Source_link