Device path optimization makes quick device servo machining with nanometer precision potential

[ad_1]

Researchers from Keio College developed a novel device path era technique for driving an independently managed quick device servo (FTS) for freeform floor machining. With out necessity of trial and error, the strategy permits speedy manufacturing of high-precision freeform optics.

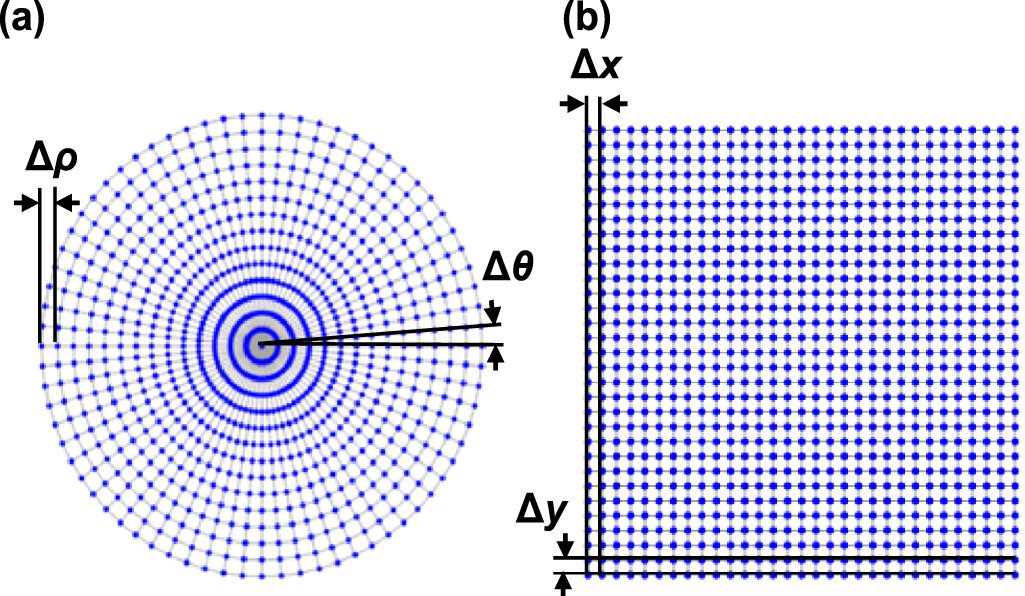

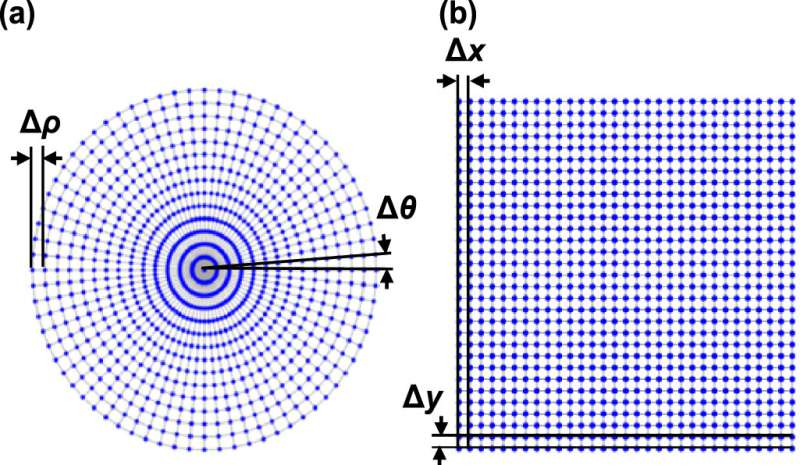

The device path program was generated utilizing the ring and mesh strategies as an alternative of the standard spiral device path. The device path was optimized by analyzing the impact of interpolation error utilizing kind error prediction.

The optimization of management factors format consists of two steps. Initially, the variety of management factors is decided. Then, the optimum side ratio of the format parameters is decided. Experimental validation by machining two-dimensional sinusoidal waves and micro-lens array demonstrated the effectiveness of the device path optimization technique proposed on this examine. The proposed technique lowered the form error from submicron to 10 nm stage for two-dimensional sinewave.

Professor Jiwang Yan commented that “FTS-based diamond turning is an incredible technique to manufacture freeform surfaces with excessive effectivity, however standard FTS items pushed by piezoelectric actuators have very small strokes in micrometer scale, limiting their functions.”

“In recent times, long-stroke FTS items, geared up with voice coil pushed air bearings, have been developed, which allow millimeter-level working strokes, and in flip, tremendously expands the functions of FTS diamond turning. To enhance the system compatibility and stability, these voice coil-based FTS items are independently pushed by separate management methods. Nevertheless, the device path era technique for such FTS has not been established but, which is considered a bottleneck.”

Yusuke Sato says that “this examine goals at proposing novel strategies to producing and optimizing the device path for the impartial FTS management system to scale back kind error of a machined floor attributable to two-dimensional interpolation. Firstly, management level clouds are pre-generated in two completely different strategies, specifically, ring technique and mesh technique.”

“Based mostly on the distribution of the management factors, the ultimate machined floor profile is predicted and interpolated by simulation. Then, by evaluating the simulated floor with the designed floor, the shape error is obtained. By repetitively adjusting the parameters of the management factors, the shape error was minimized to the specified tolerance.”

This examine establishes an essential base for additional growing ultraprecision machining applied sciences of freeform optics by diamond turning by utilizing a FTS unit with a separate controller to realize excessive accuracy with out necessity of trial and error, which contribute to superior manufacturing of excessive value-added merchandise.

Professor Yan says that “the developed device path era/optimization system makes the commercially obtainable FTS items extra exact and highly effective. It’s particularly helpful to enhance the productiveness of freeform optics that are extensively employed in varied merchandise resembling VR/AR methods, cameras, scanners, head-mounted shows, and elements utilized in aerospace and biomedical engineering. Fast manufacturing of such freeform surfaces could change the ideas of product design within the close to future.”

The analysis was printed within the Worldwide Journal of Excessive Manufacturing.

Yusuke Sato et al, Device path era and optimization for freeform floor diamond turning primarily based on an independently managed quick device servo, Worldwide Journal of Excessive Manufacturing (2022). DOI: 10.1088/2631-7990/ac5f12

Supplied by

Worldwide Journal of Excessive Manufacturing

Quotation:

Device path optimization makes quick device servo machining with nanometer precision potential (2022, October 5)

retrieved 24 December 2022

from https://techxplore.com/information/2022-10-tool-path-optimization-fast-servo.html

This doc is topic to copyright. Aside from any truthful dealing for the aim of personal examine or analysis, no

half could also be reproduced with out the written permission. The content material is offered for data functions solely.

[ad_2]

Source_link